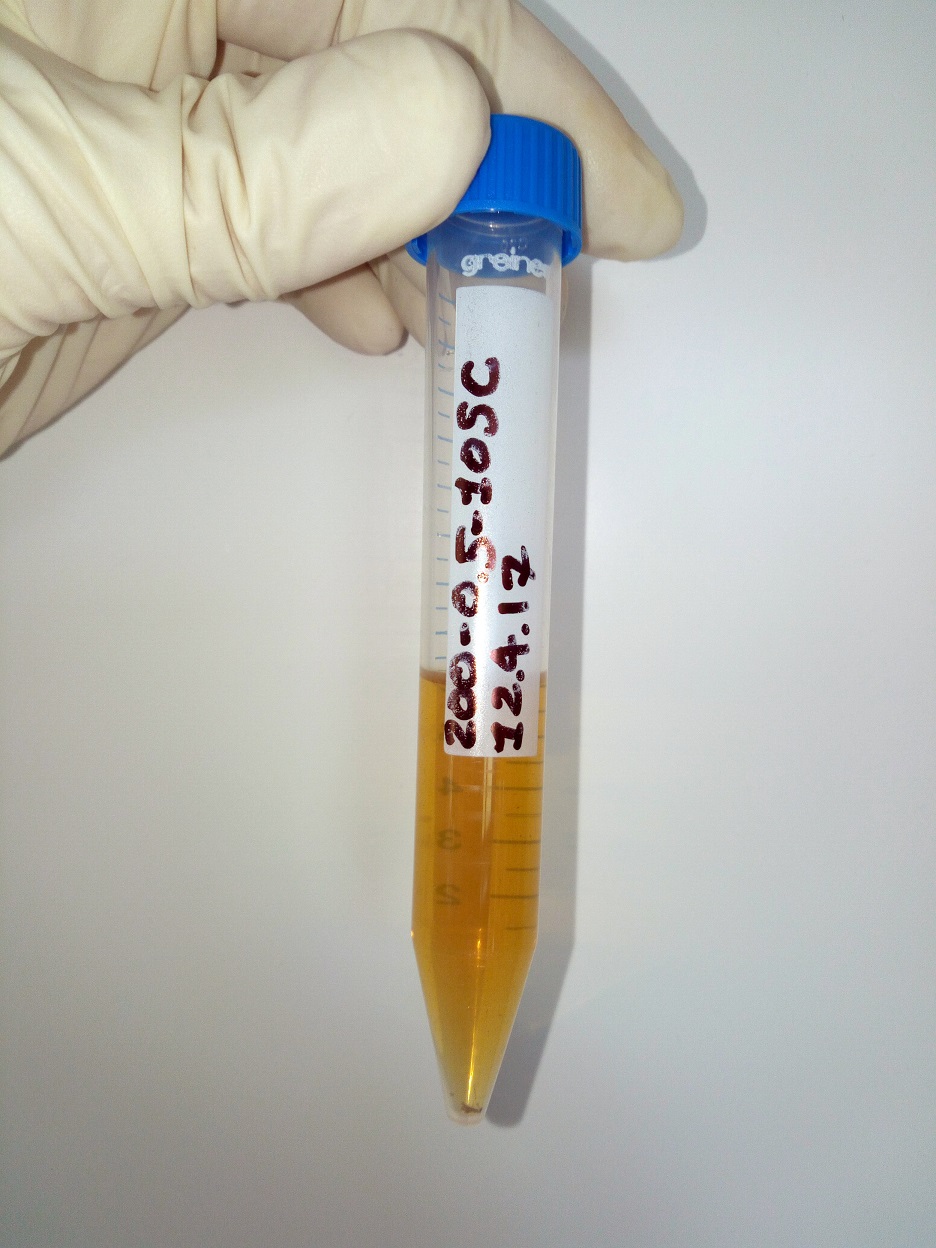

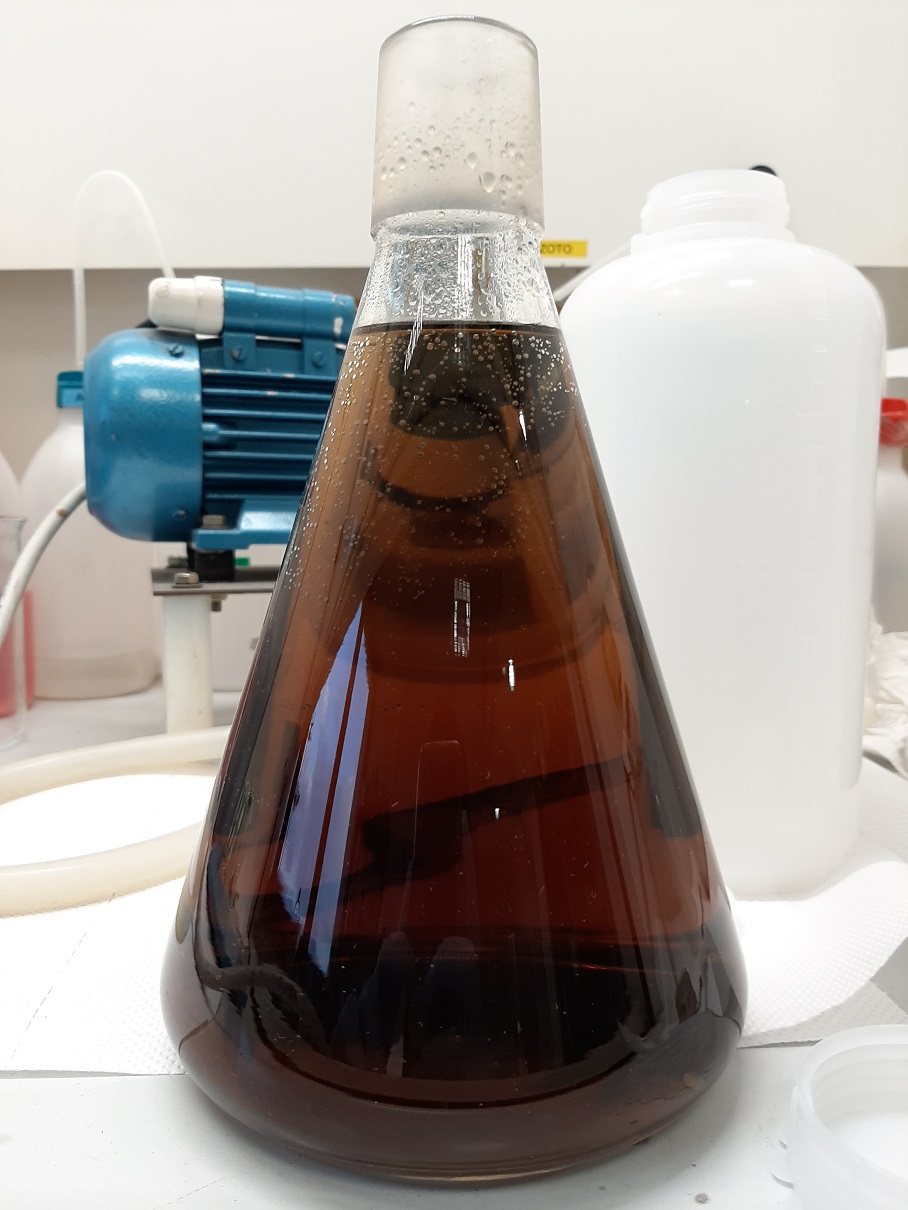

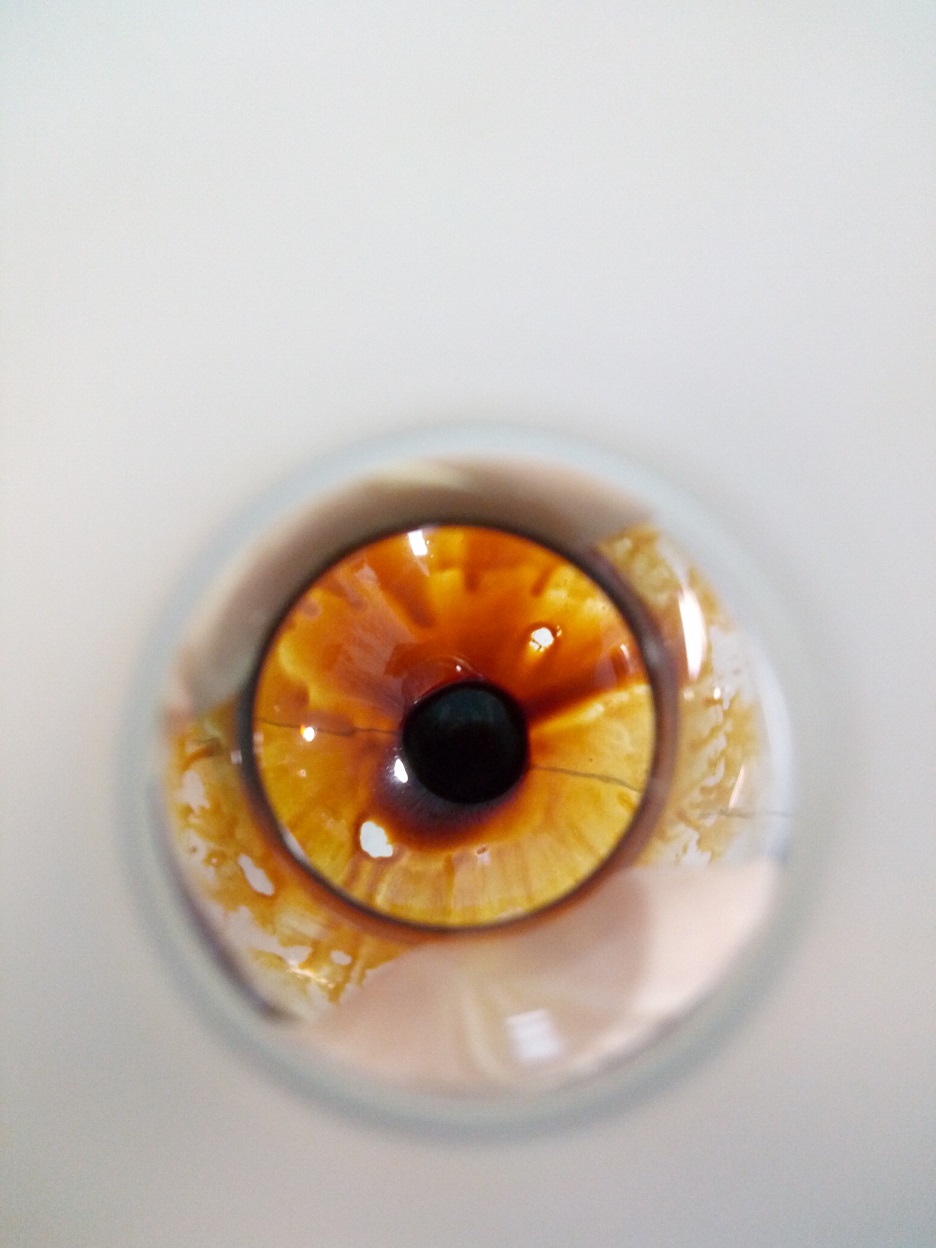

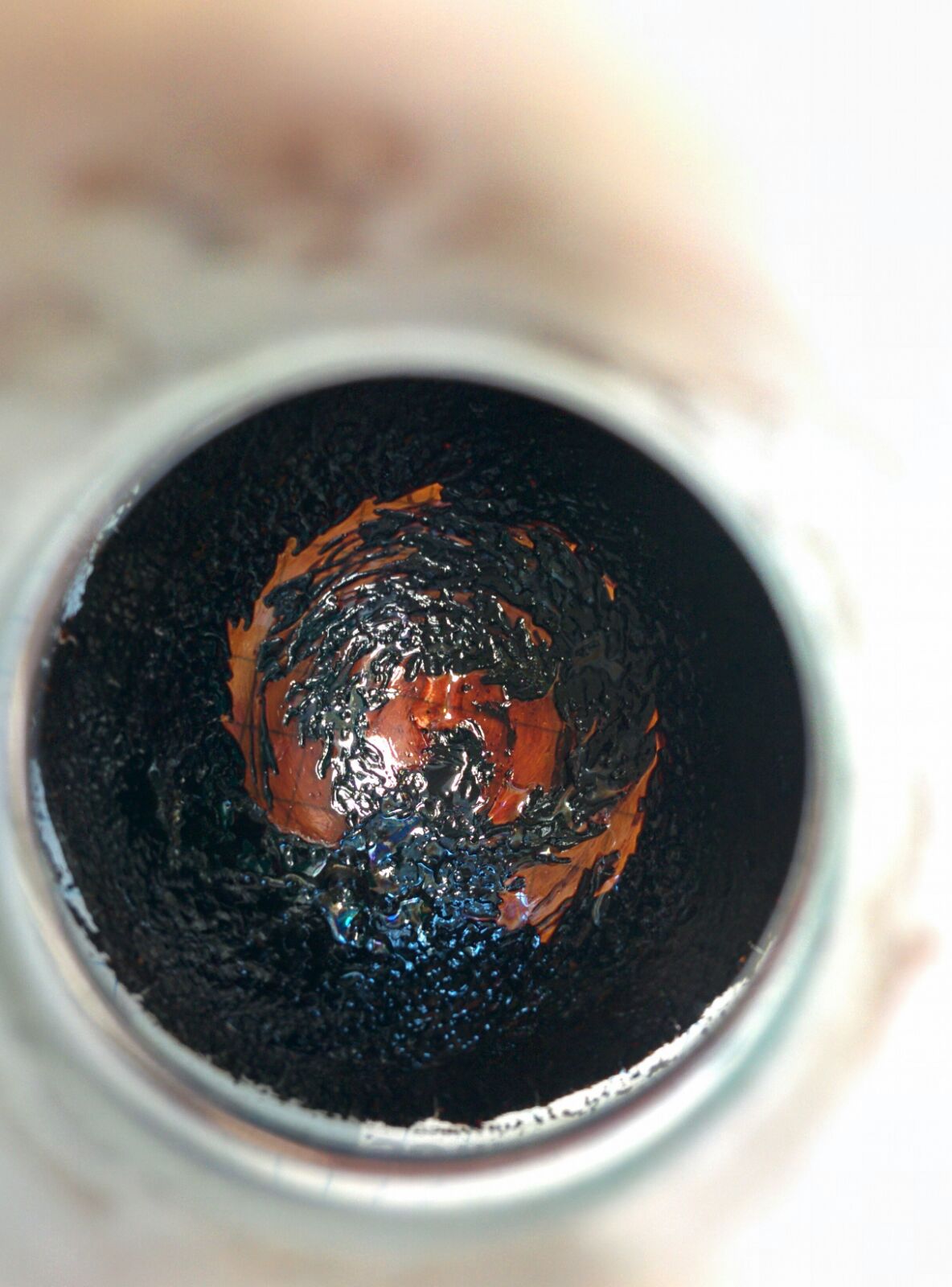

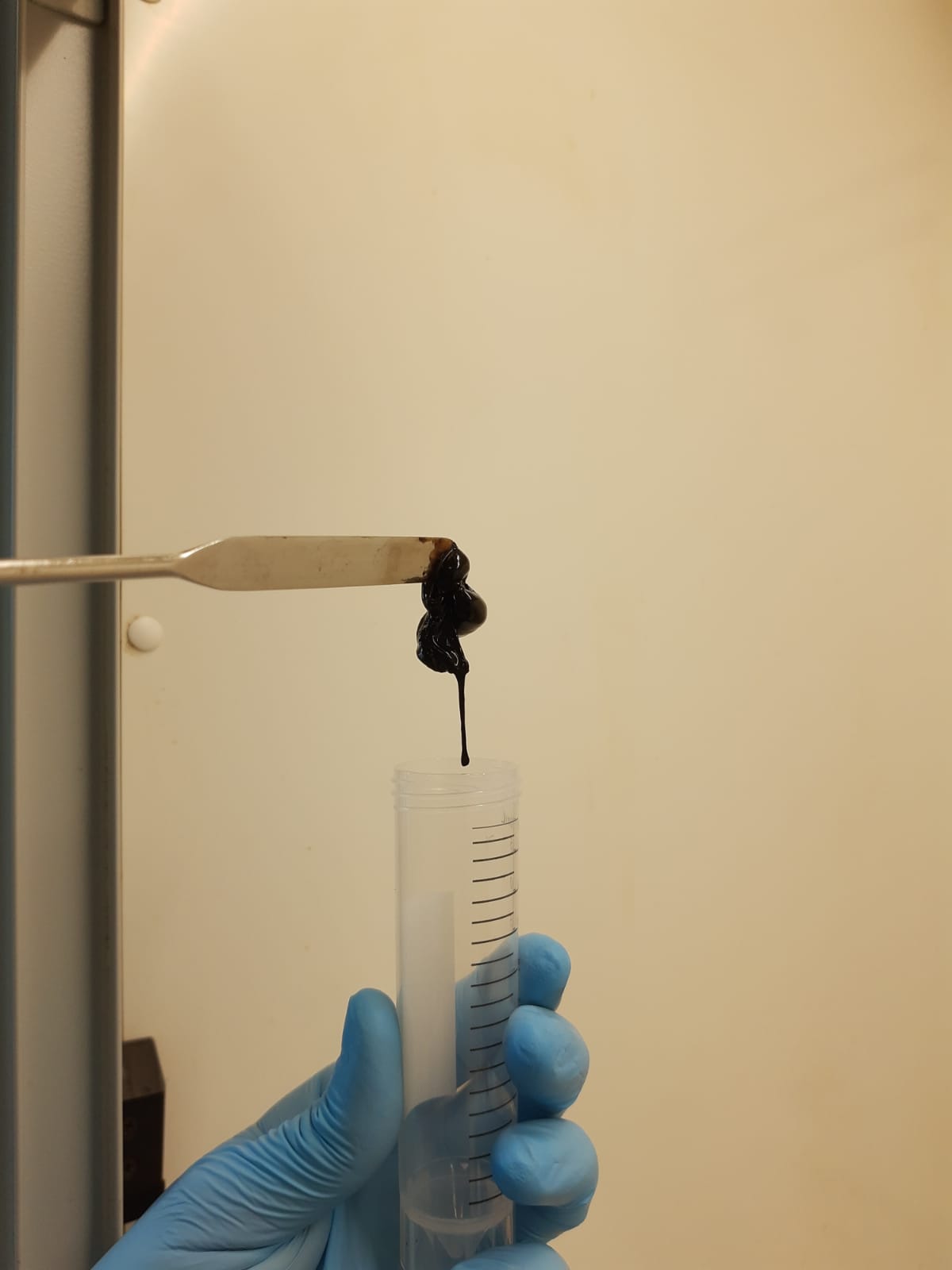

Hydrothermal processing consists in the conversion of organic material in a hot compressed water or aqueous solution. This reaction environment makes this process highly indicated for treating very wet materials, like micro/macroalgae, sewage sludge, digestate and manure. Products are char, bio-oil, aqueous phase with dissolved organics and permanent gases. As water critical point is approached and surpassed three different hydrothermal processes are defined: hydrothermal carbonization, liquefaction and gasification.

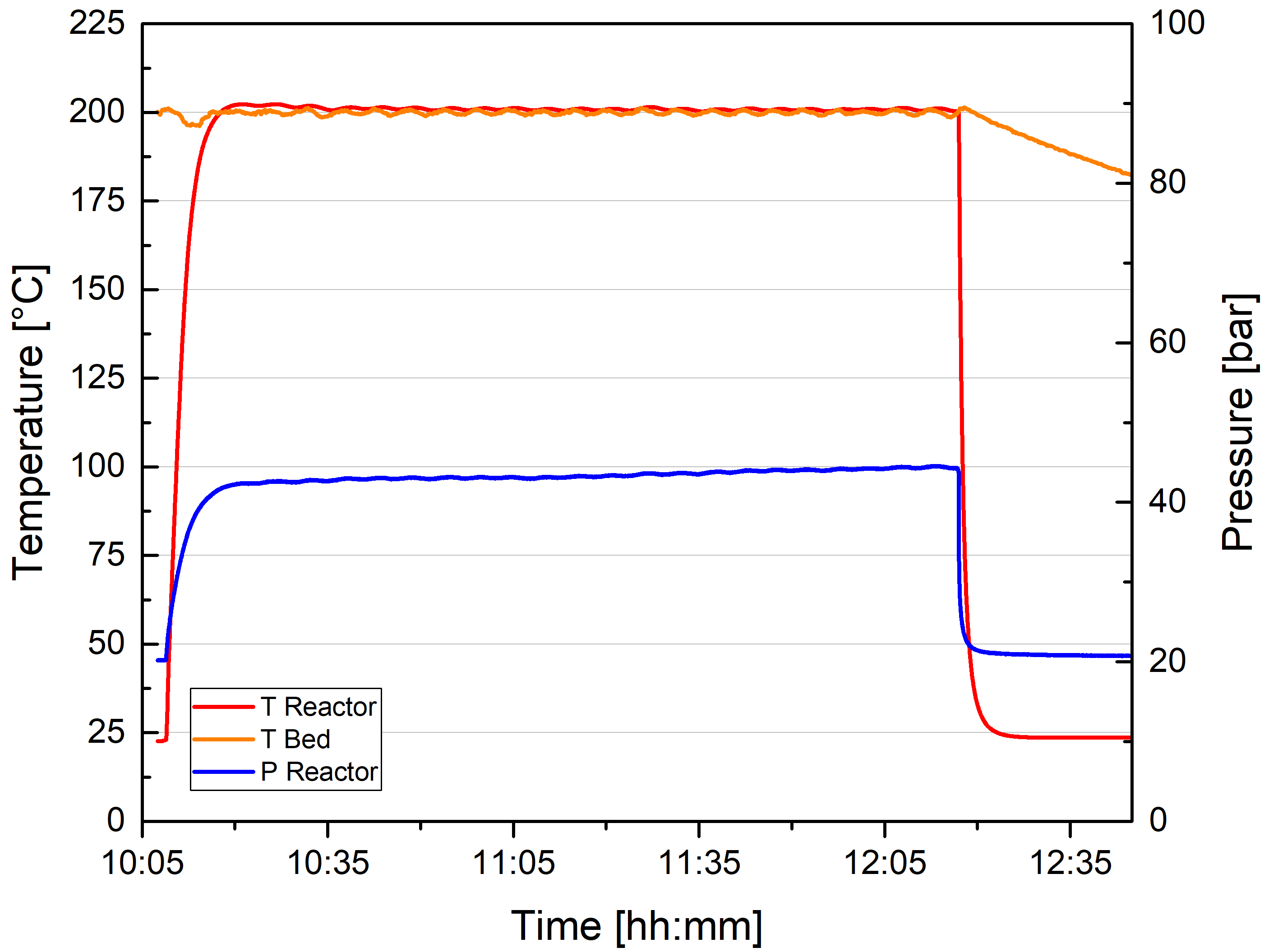

RE-CORD has achieved relevant know-how on hydrothermal conversion of biomass for biofuel precursors or bioproducts production. Sub and critical processes, such as hydrothermal carbonization (HTC) and hydrothermal liquefaction (HTL), can be rapidly investigated in RE-CORD batch systems, consisting in two Parr autoclaves (160 ml) and one in-house developed micro-reactor test bench (MRTB, up to 80 ml). These batch systems are particularly valuable in the systematic investigation of the effect of different feedstock and process conditions on products distribution, quality or properties. Particularly RE-CORD’s MRTB offers superior performances in terms of process control and heating/cooling rate with respect to autoclaves, as it adopts a hot fluidised sand bath as heating medium. Moreover, it is equipped with pressure/temperature sensors and high-pressure relief systems. Its flexibility, moderate operating cost and high availability makes it the ideal companion of most research, from preliminary screening to process optimization.

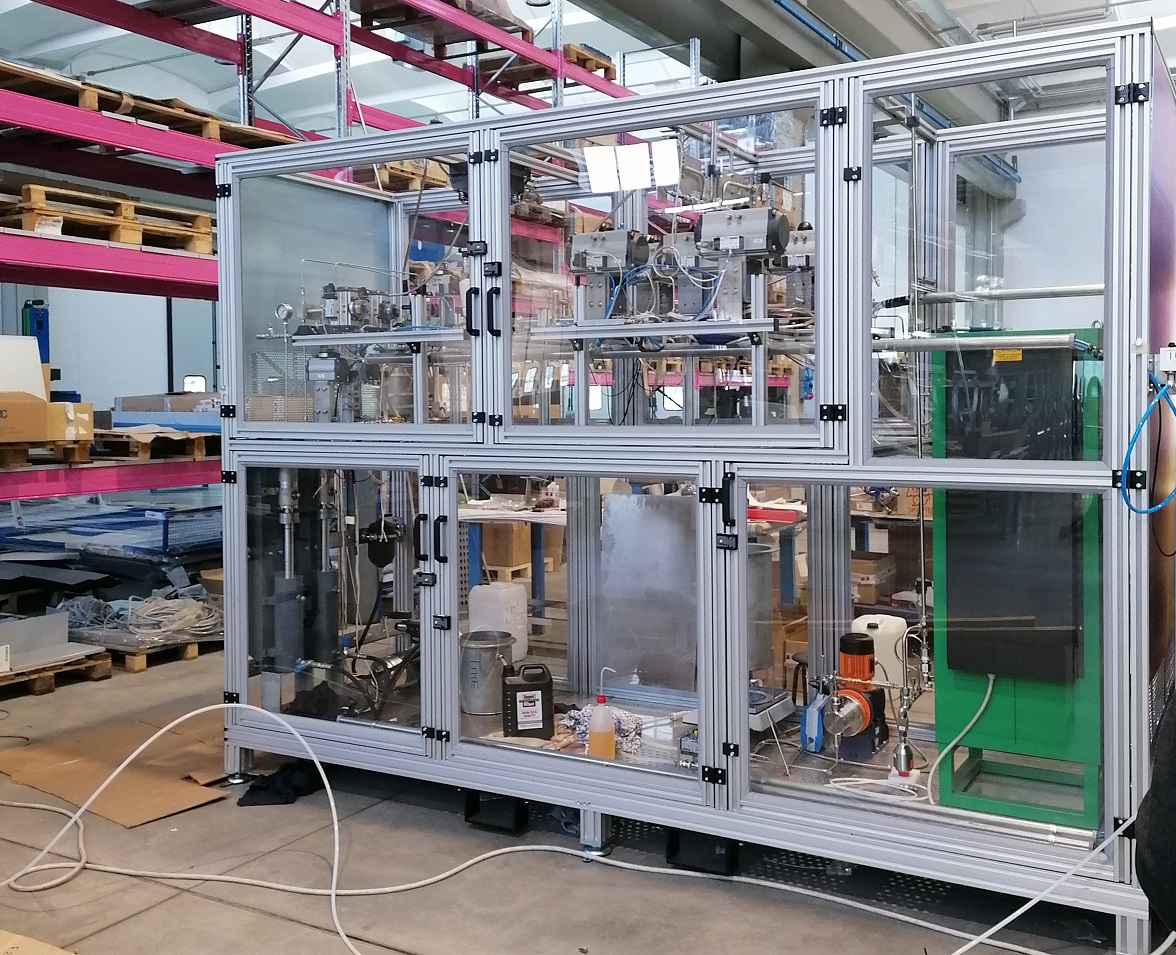

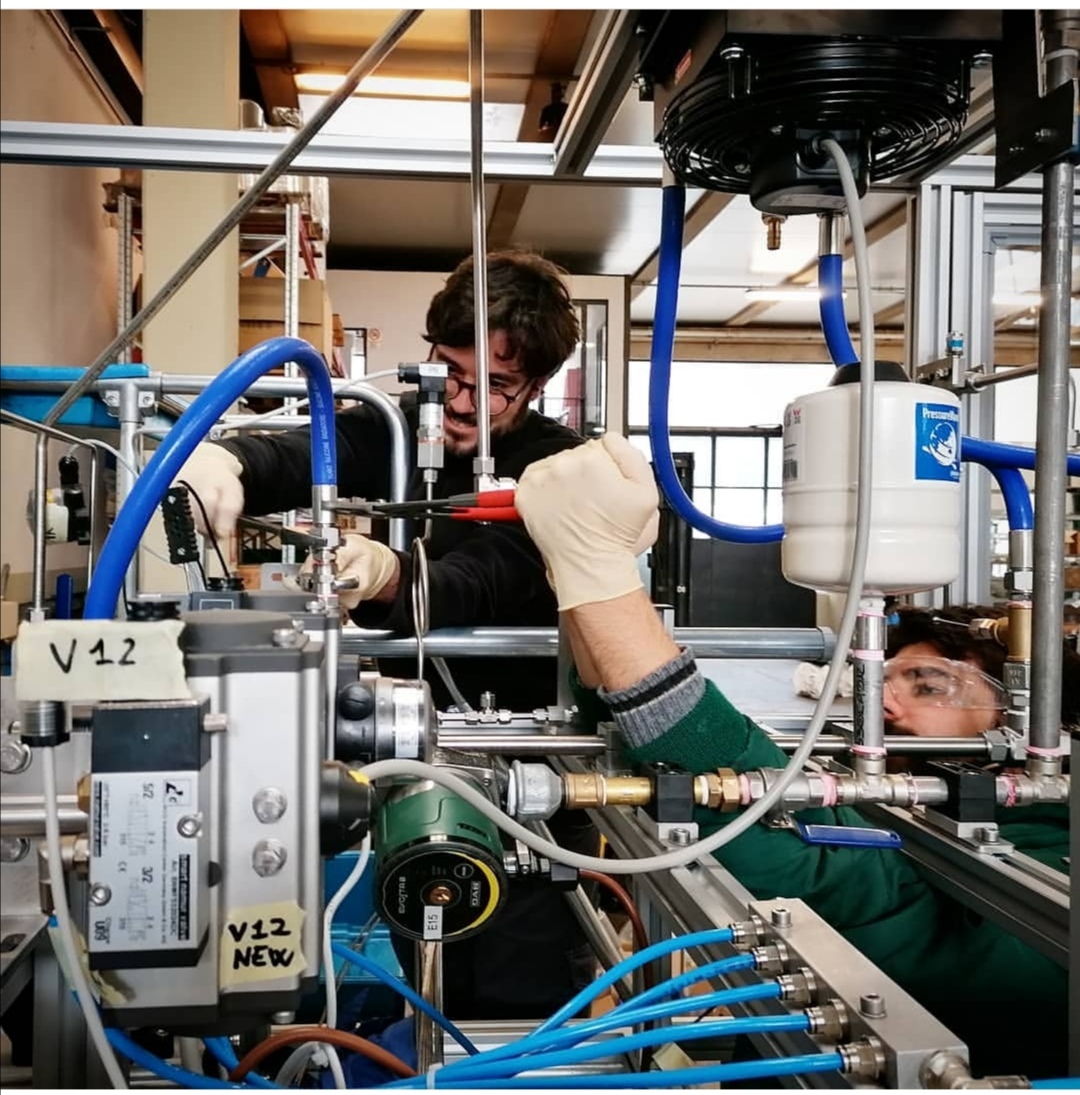

In addition, RE-CORD has developed a continuous hydrothermal liquefaction unit, where the results from the batch experiments can be validated in a continuous system. The continuous plant can elaborate more than 1.5 l/h of slurry, it is equipped with a high-pressure positive displacement pump and two different pressure let-down systems, which are adopted alternatively.