RE-CORD has collected more than 10 years of experience in the fiel of pyrolysis with EU-supported projects, collaboration with large industries and international scientific works (as reported in our publications). Thanks to the resulting solid expertise RE-CORD can offer R&D highly qualified services for pyrolysis units. RE-CORD can design and engineer pyrolyzers to convert biomass and wastes into bio-products, biofuels and bioenergy. In addition, thanks to the pilot units available at our experimental facilities, we could perform pyrolysis test of biomass and wastes for the costumers, as well as the analysis of the products at RE-CORD laboratory.

The traditional process of pyrolysis consists in the chemically decomposition of organic material by heating in the absence of Oxygen, at atmospheric pressure, and in a temperature range between 300 and 600 ⁰C. Pyrolysis products of biomass are char, bio-oil and permanent gases. Depending on the hot vapours residence time into the reactor, pyrolysis could be: fast, intermediate and slow. Moreover, the presence of catalysts during process can improve the products quality or yield, favouring the production of desired compounds, such as fuels and chemicals.

Biomass slow pyrolysis, or also called carbonization, is the process of converting solid, lignocellulosic biomass into charcoal. It is currently operated at several scales, encompassing manual, rudimental batch methods and industrial, continuous systems, with reported throughput up to several tens of thousands ton per year. Since 2013 RE-CORD has been developing an innovative biomass carbonization process (“CarbOn”, Pantent IT1429282) and is currently operating the first pilot plant, rated for a capacity of 50 kg/h, based on its proprietary layout.

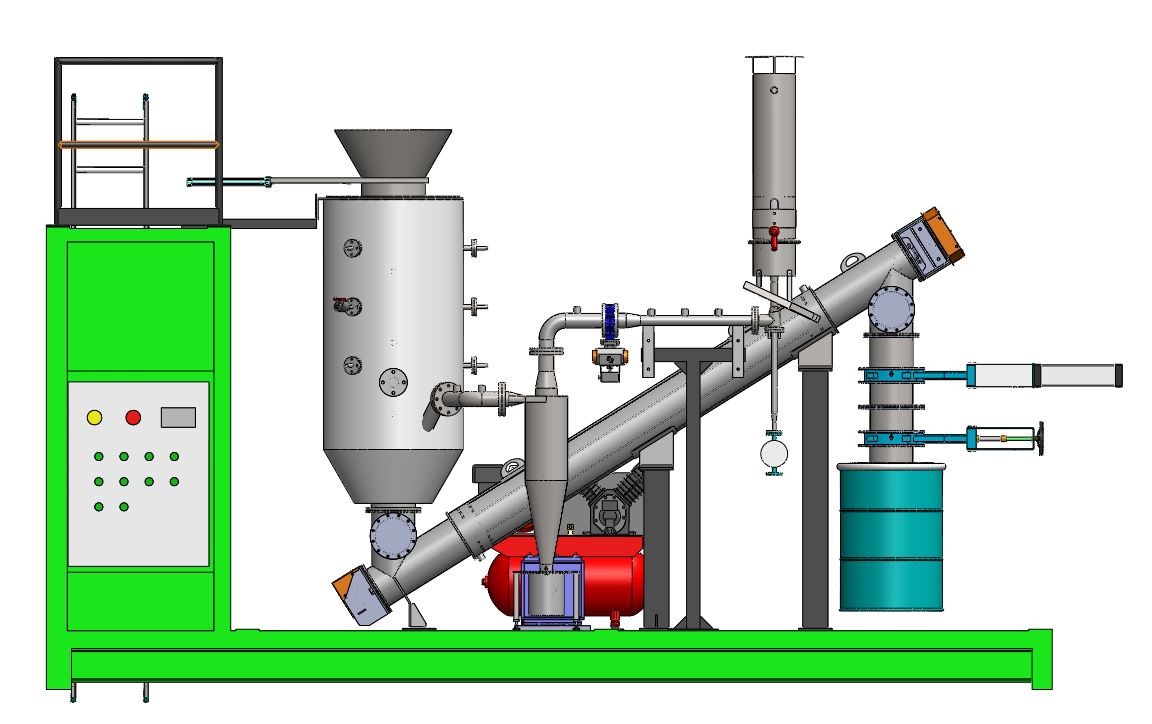

The CarbOn pilot plant is a continuous biomass carbonization system based on open top, downdraft technology, operating in oxidative pyrolysis. The main features are:

The pilot is essentially composed by three sections: (1) loading and conversion of biomass; (2) charcoal discharge and cooling system; (3) extraction and burning of the pyrolysis vapors.

The plant, made in stainless steel (AISI 304 and 316) and supported on a self-standing 6x2.5 m structure, is rated for 50 kg/h of biomass with up to 20 wt% moisture content.

In general, pyrolysis of woodchips produces 25-30% in mass of charcoal with a carbon content up to 85%. This is roughly correspond to the 50% of energy output from the reactor. The other 50% part is energy available in the hot gases, which could be burned for heat generation.

The rotating kiln unit is a carbonization pilot plant that allows to convert a broad range of feedstock into biochar, at a scale of operations of TRL7. The pilot unit is composed of an externally heated rotating kiln (pyrolysis reactor), a refractory-lined combustion chamber for post-combustion of pyrolysis vapors, and a gas-to-water heat-exchanger for the exhaust fitted with a dry-cooler. The plant can convert approximately 100 kg/h of biomass in biochar and heat, using natural gas as start-up and pilot fuel for the two dual-fuel burners - one fitted into the kiln assembly, one into the post-combustion chamber. The volatiles evolved during pyrolysis are extracted by a fan and sent to either or both the burners, while char is separately recovered.

The intermediate pyrolysis unit PYRO available in RE-CORD experimental area is designed and developed to test different type of biomass and organic wastes.

PYRO has an independent feeding sections for liquids (e.g. used cooking oil) and solid biomass (wood), an electrically heated reactor, internally stirred, a condensation train and discharge ports for solid and gases. Volatiles produced during pyrolysis are extracted by a fan placed in the cold section, downstream of the condensation system, where they separate into a pyrolysis liquid, that is collected, and an off-gas stream composed of permanent gases, which is vented outside. Unlike liquid and gases, collection of the solid residue is performed batch-wise at the end of each test.

PYRO can be operated up to 1.5 kg/h of finely ground biomass, 1 l/h of liquid feed, and the maximum operating temperature is 600°C and the average vapour residence time is in the range of 5 – 30 s. It can operate at different temperatures and biomass residence times, adapting its operation on the feedstock that has to be processed. The unit is generally adopted to process small volumes of biomass (up to 10 kg) to provide data about its potential in terms of “traditional” pyrolysis and eventually, torrefaction.

RE-CORD’s continuous intermediate pyrolysis unit is able to process approximately up to 3 kg/h of biomass, is an auger type reactor and can be operated up to 600°C. Solid biomass is introduced into the reactor by a dosing screw through a double gate-valve system which provide air-tightness for the process. The rotating speed of the reactor screw can be easily adjusted to vary the solids residence time, from few minutes up to 1 hour, in order to investigate the effect of the latter on the pyrolysis products and their quality. The reactor is equipped with an auxiliary gas injection port section, which allow the entrance of inert(s) or oxidant(s) into the reactive atmosphere to study different move of pyrolysis (e.g. oxidative or inert pyrolysis). The reactor has three main independent heating sections, used to effectively control the heating rate and provide an extra degree of flexibility. Volatiles produced during the process are constantly withdrawn by a fan, which is placed after the condensation unit, which consists in multiple in-series, water-cooled, surface heat exchangers. Solids are discharged in a sealed vessel, where they are collected.